Search This Supplers Products:Hollow SectionsSteel pipesSteel tubesBuilding materialSquare PipeRectangular Pipe

Comparison between straight seam steel pipe and spiral steel pipe

publisherTianjin Yuantai Derun Steel Pipe Manufacturing Group Co., Ltd.

time2023/01/03

- The production process of straight seam steel pipe is relatively simple. The main production processes are high-frequency welded straight seam steel pipe and submerged arc welded straight seam steel pipe. Straight seam steel pipe has high production efficiency, low cost and rapid development.

The strength of spiral steel pipe is usually higher than that of straight seam steel pipe. The main production process is submerged arc welding.

Comparison between straight seam steel pipe and spiral steel pipe

1. Production process comparison

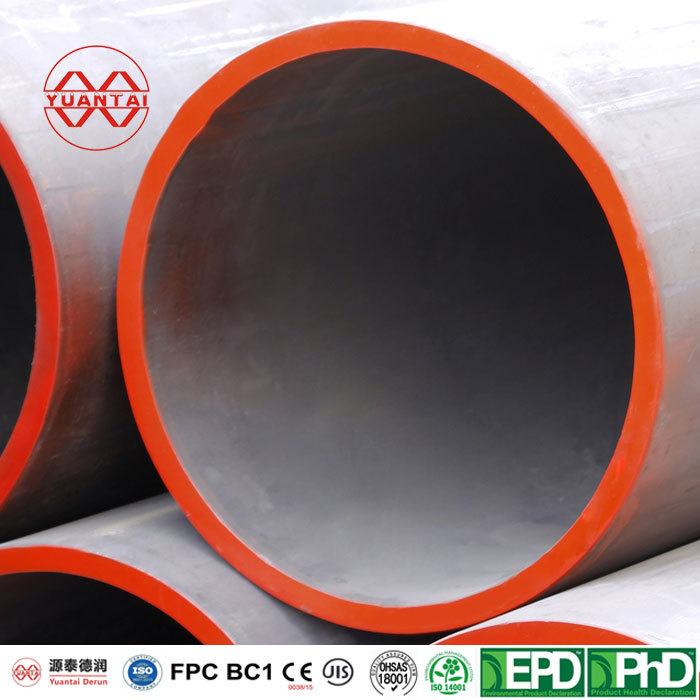

The production process of straight seam steel pipe is relatively simple. The main production processes are high-frequency welded straight seam steel pipe and submerged arc welded straight seam steel pipe. Straight seam steel pipe has high production efficiency, low cost and rapid development.

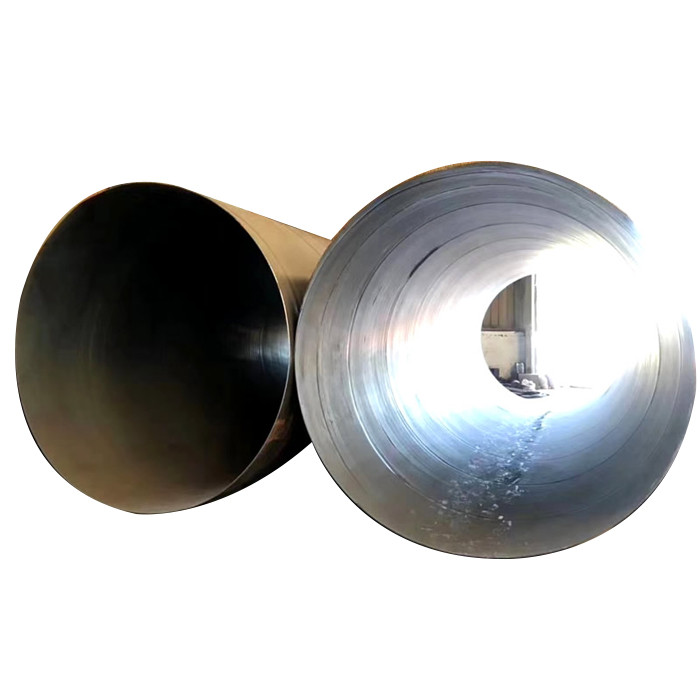

The strength of spiral steel pipe is usually higher than that of straight seam steel pipe. The main production process is submerged arc welding. Spiral steel tubes can produce welded tubes with different diameters of billets of the same width, or welded tubes with larger diameters from narrow billets.

However, compared with straight seam steel pipes of the same length, the welding length has increased by 30% and 100% respectively, and the production speed is low. Therefore, large diameter steel pipes are mostly welded by spiral welding, and small diameter steel pipes are mostly welded by straight seam welding.

When producing large-diameter straight seam steel pipes in industry, T-shaped welding technology is used, that is, a small number of straight seam steel pipes are butt jointed and connected to meet the required length of the project. The defects of T-shaped straight seam steel pipe will be greatly increased, and the welding residual stress of T-shaped weld is large. The weld metal is usually under triaxial stress, which increases the possibility of cracking.

In addition, according to the technical regulations of submerged arc welding, each weld shall be subject to arc striking and arc extinguishing treatment. However, each steel pipe cannot meet this condition during circumferential seam welding, so more welding defects may occur during arc extinguishing.

2. Comparison of performance parameters

When the pipe is subjected to internal pressure, two main stresses are usually generated on the pipe wall, namely radial stress and axial stress. Comprehensive stress at the weld, where α It is the weld spiral angle of spiral steel pipe.

The comprehensive stress at the spiral weld is the main stress of the straight seam steel pipe. Under the same working pressure, the wall thickness of spiral steel pipes with the same pipe diameter is smaller than that of straight seam steel pipes.

When parallel defects appear near the spiral weld, the expansion risk of the spiral weld is less than that of the straight weld because of the small force of the spiral weld. Since the radial stress is the maximum stress on the steel pipe, the weld bears the maximum load in the vertical stress direction. The joint bears the maximum load, the circumferential weld bears the minimum load, and the spiral weld bears the load between the two.

The development trend of pipeline is large diameter and high strength. With the increase of steel pipe diameter and steel grade, the trend of stable expansion of ductile fracture tip is greater. Although spiral steel pipe and straight seam steel pipe have the same grade, spiral steel pipe has higher impact toughness.